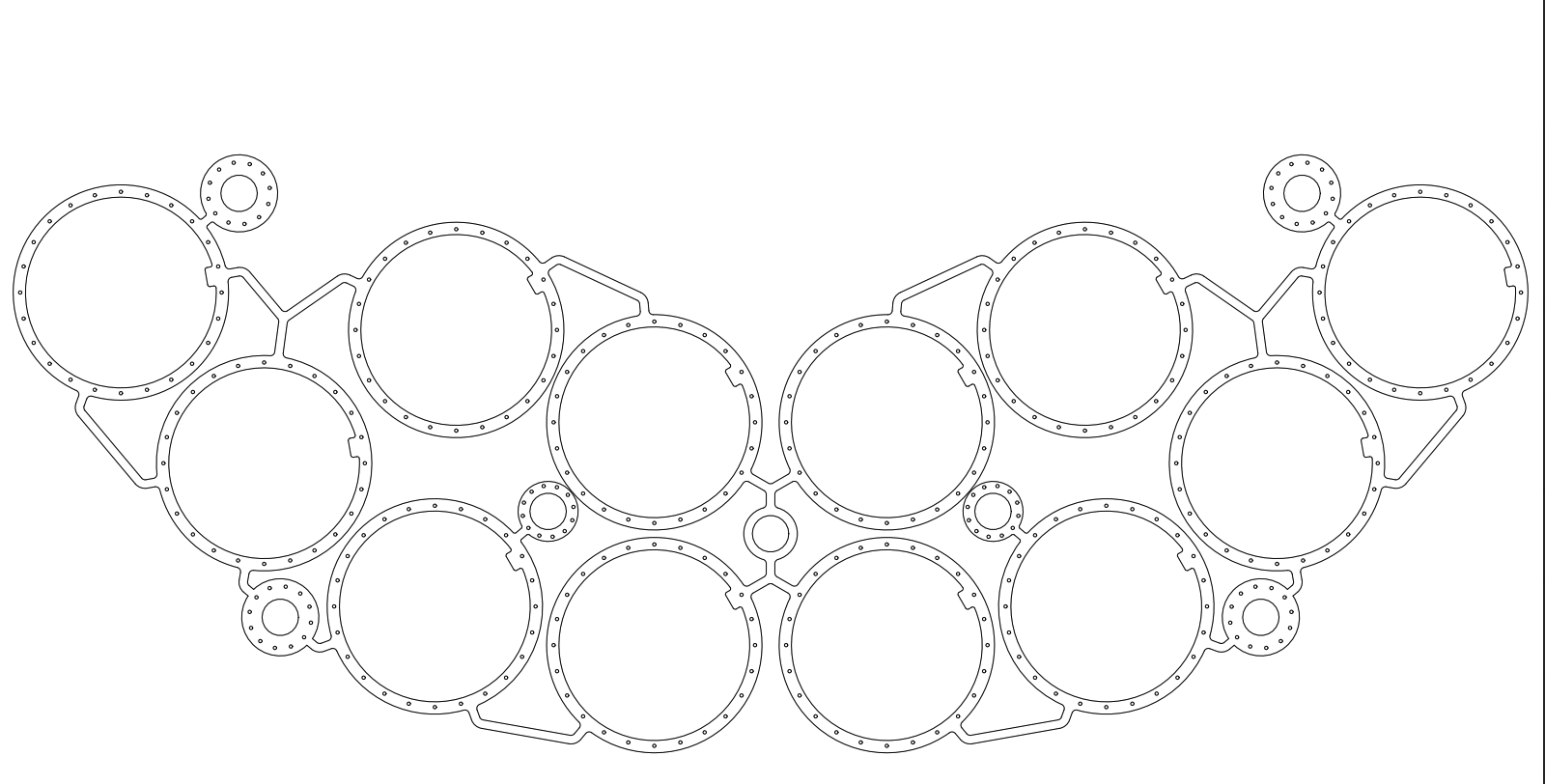

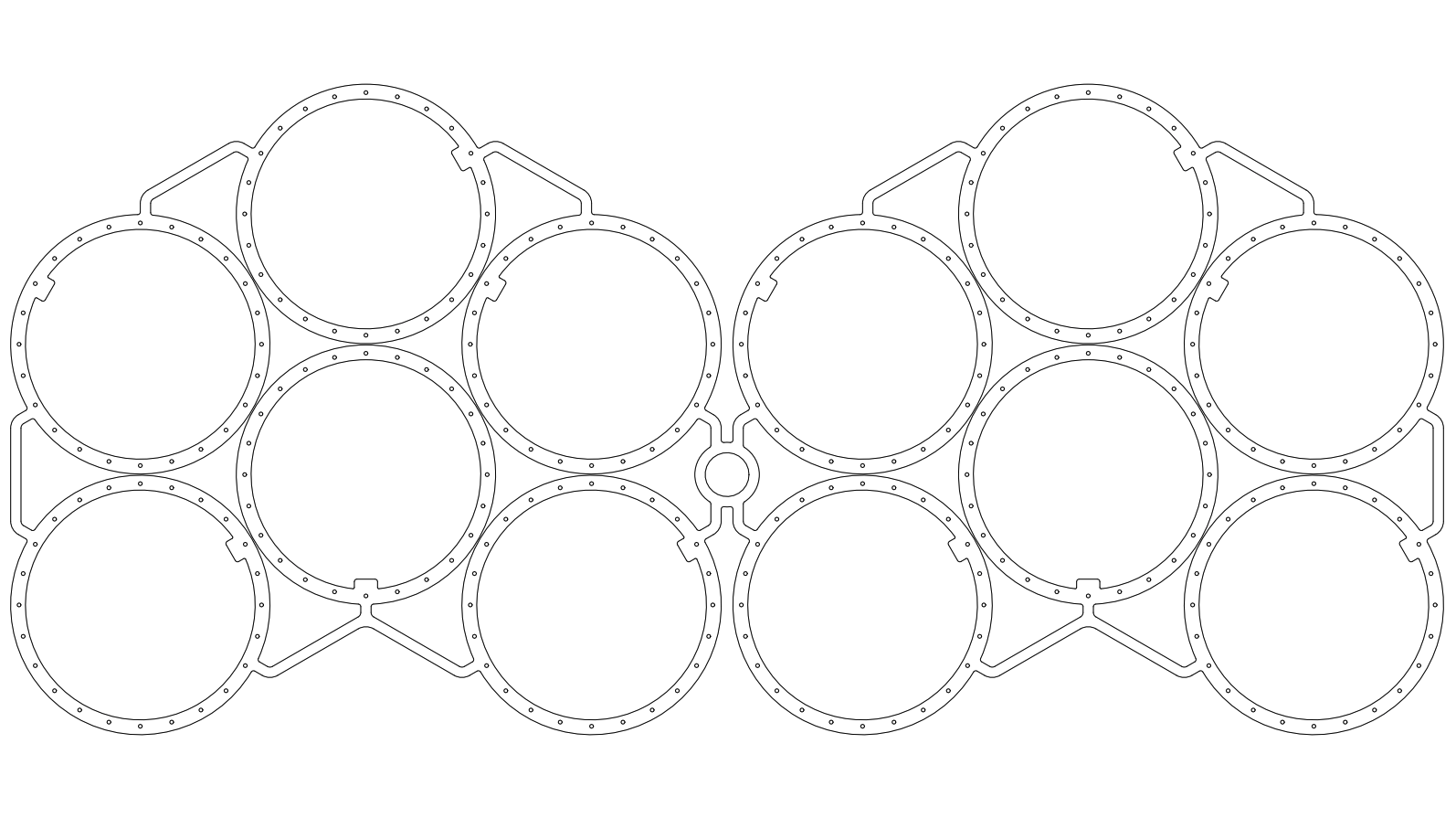

Position guides are the backbone of a successful DevKit build, ensuring consistent sensor orientation and precise spacing across the flexible cap. You may utilize Kernel’s standardized library or develop custom guides tailored to your specific montage.

Design Files & Templates

The following templates are provided as .DXF reference files. If your workflow requires .PDF, .STEP, or .STL formats, please contact Kernel Support.

| DXF file | Image |

|---|---|

| |

| |

| |

| |

| |

| |

| |

|

The provided .STEP file is a 3D model of a NIOSH medium reference headform marked with 10-10 layout EEG positions. A 3D print of this file is useful for aligning module or EEG position guides to the desired location(s) before stitching in place.

Custom Design Specifications

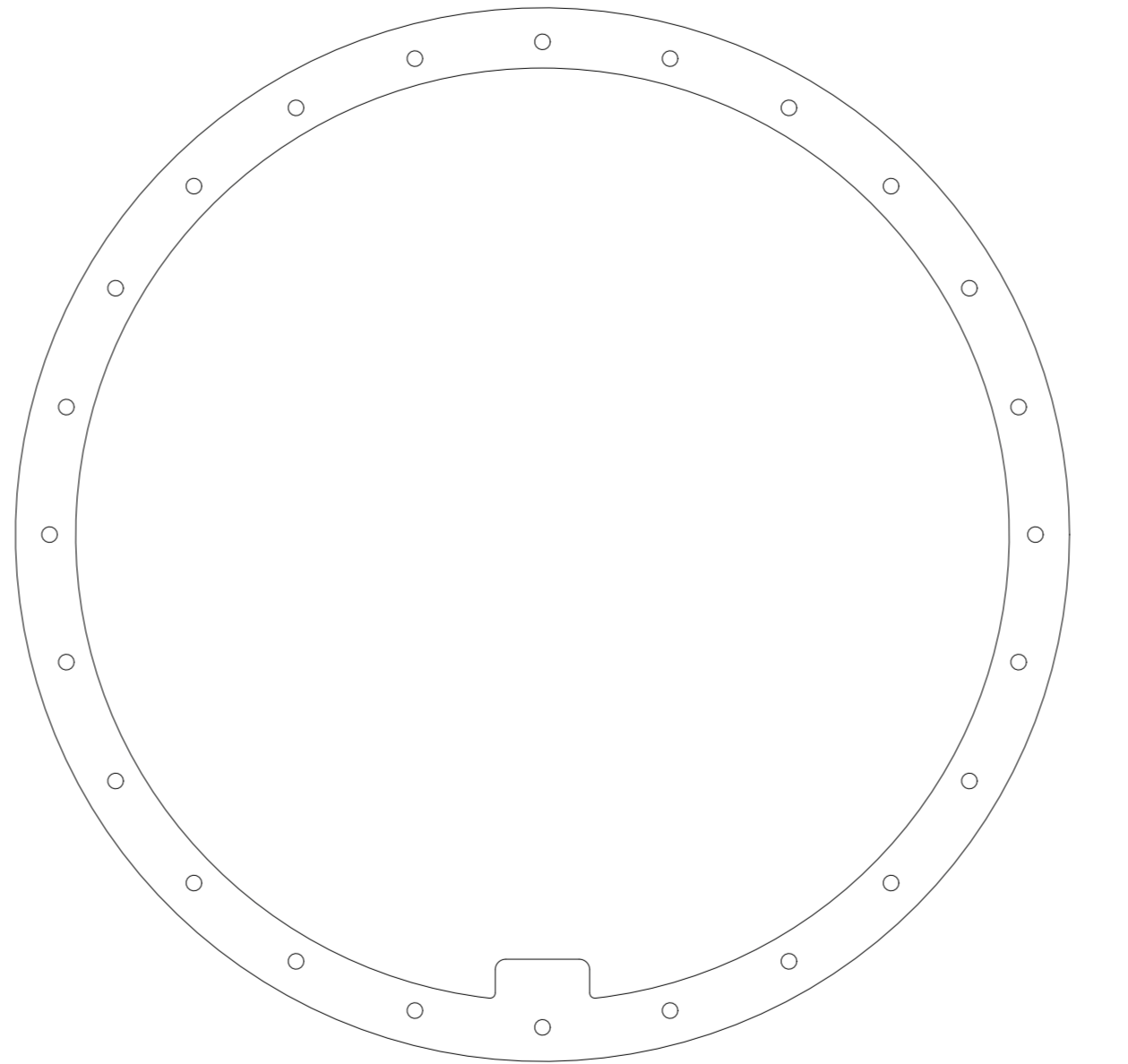

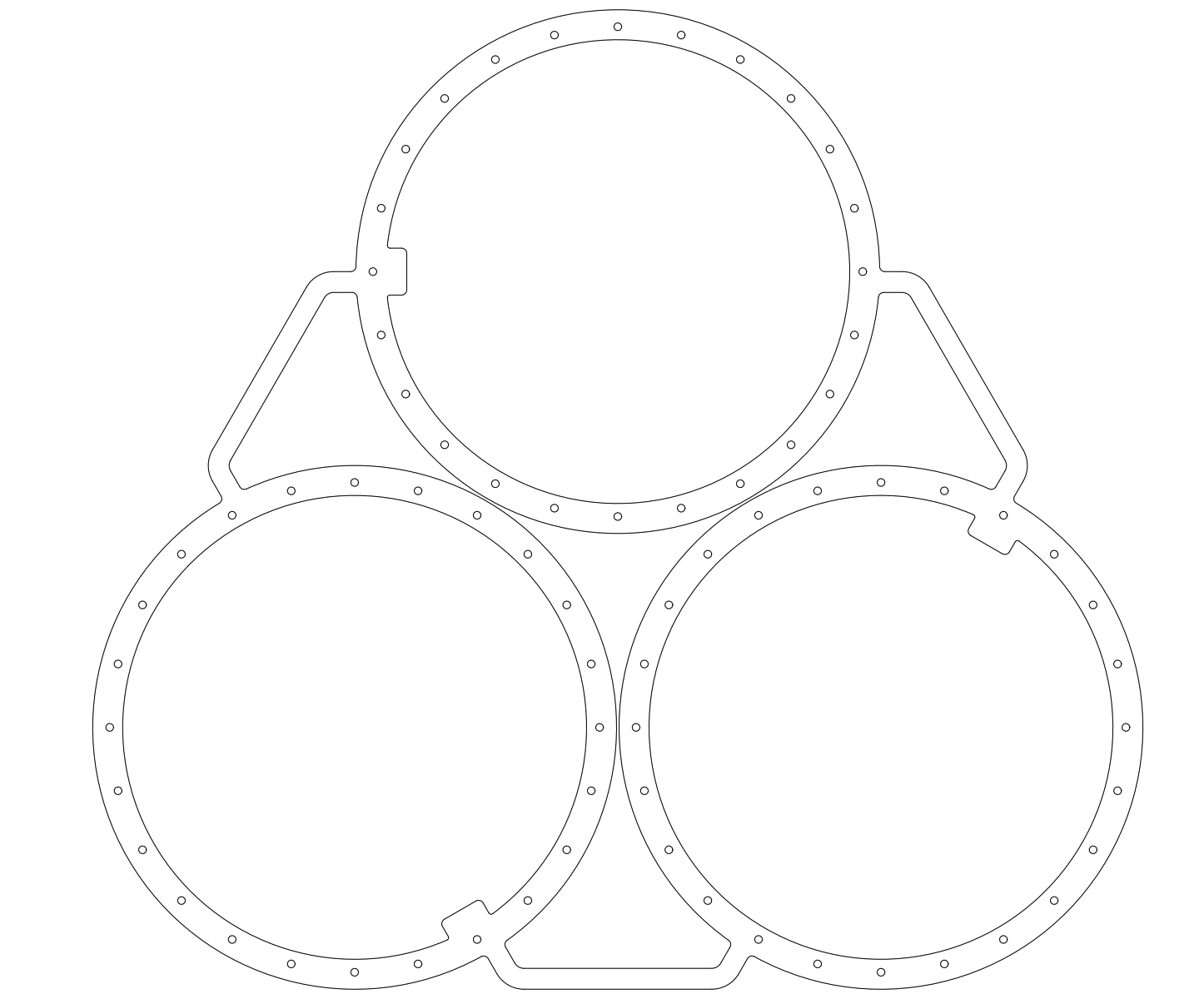

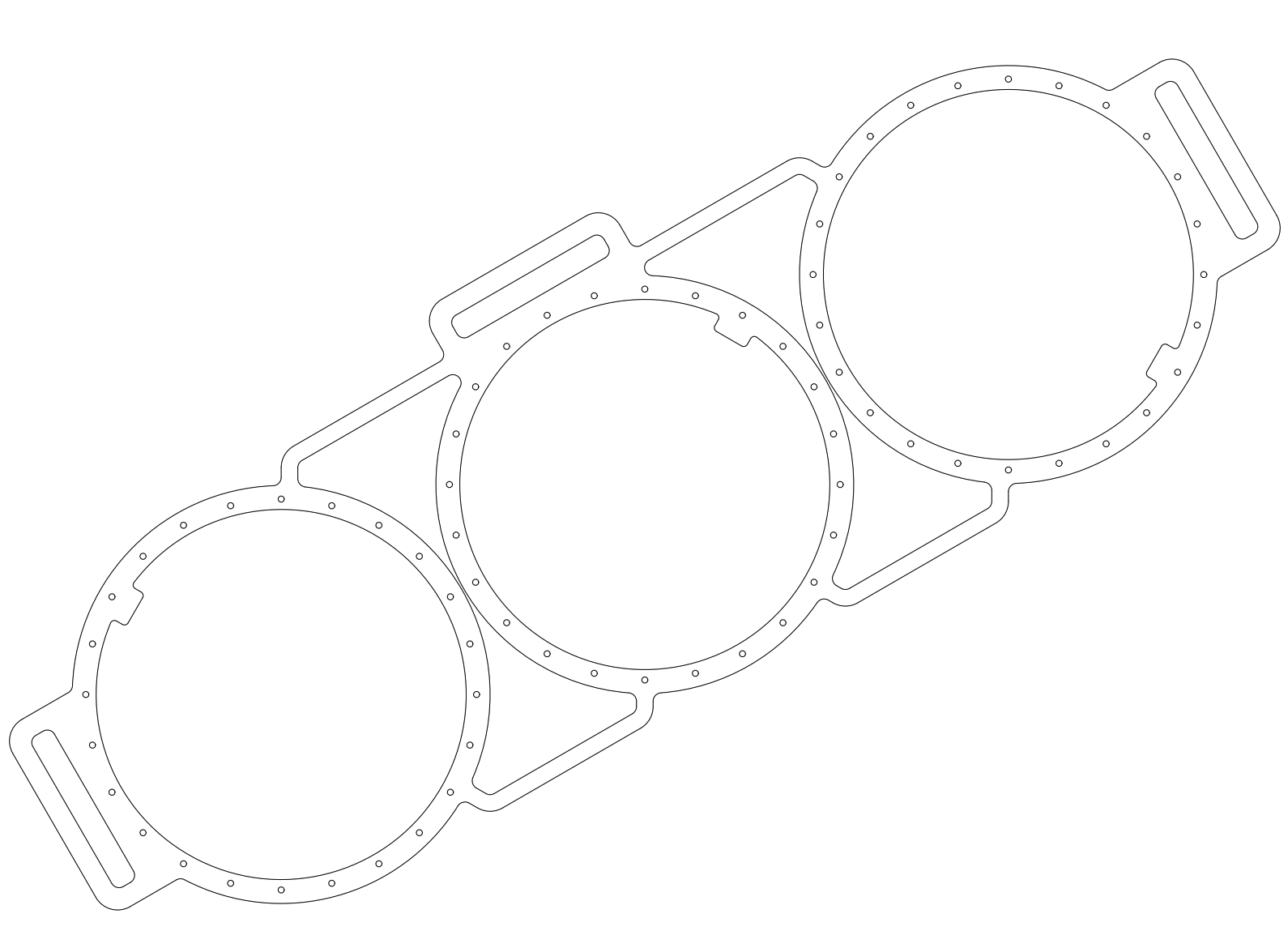

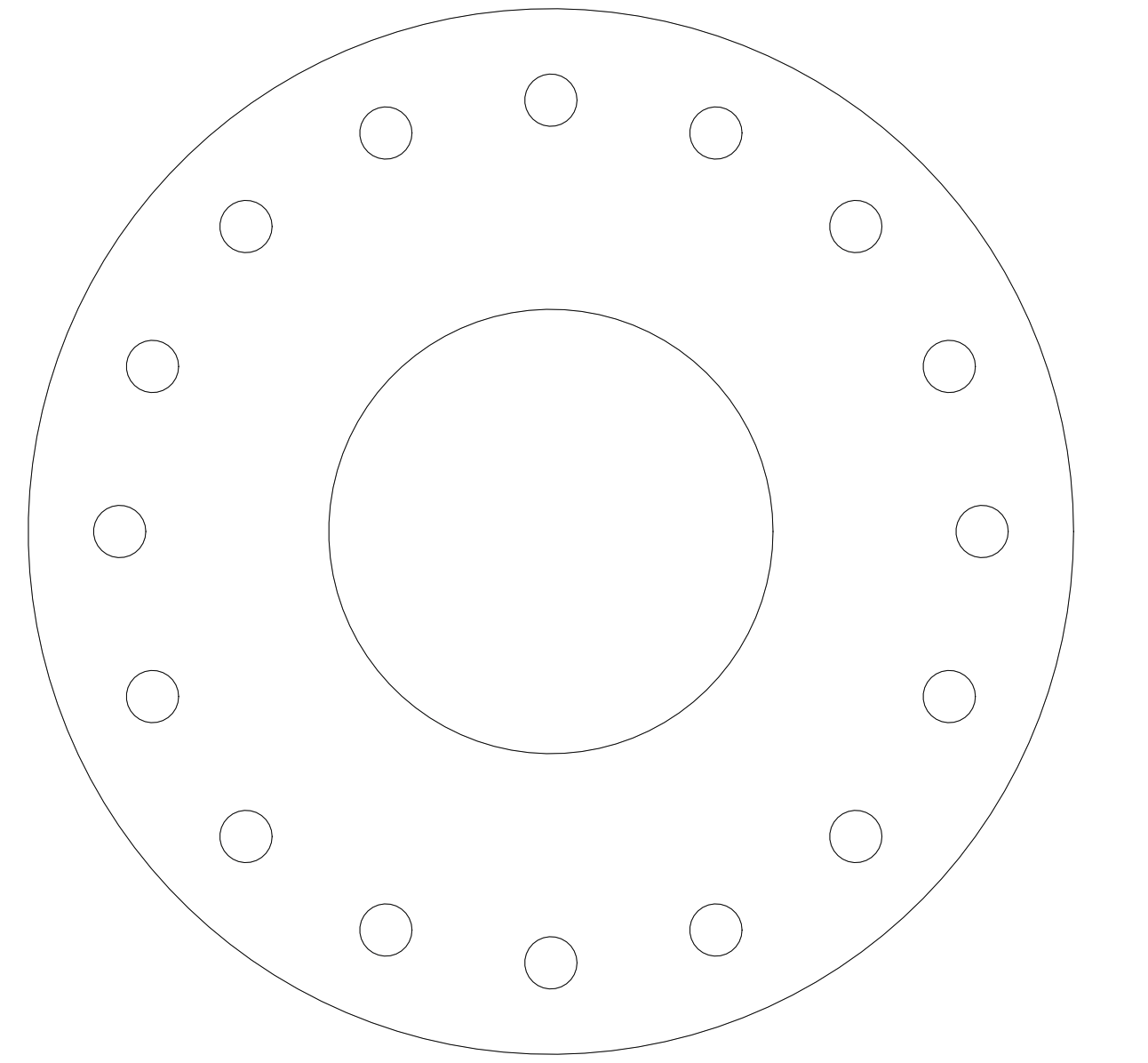

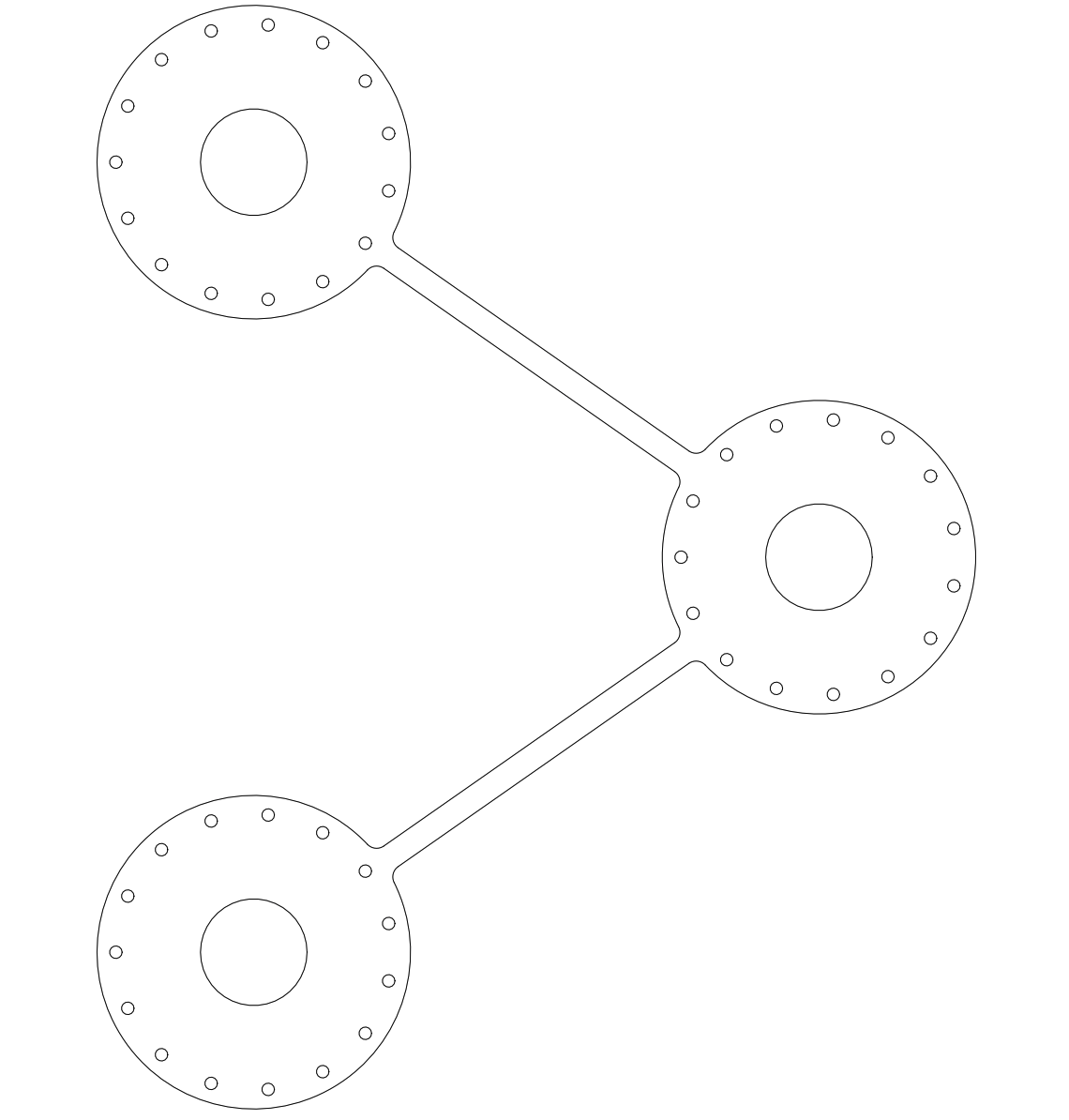

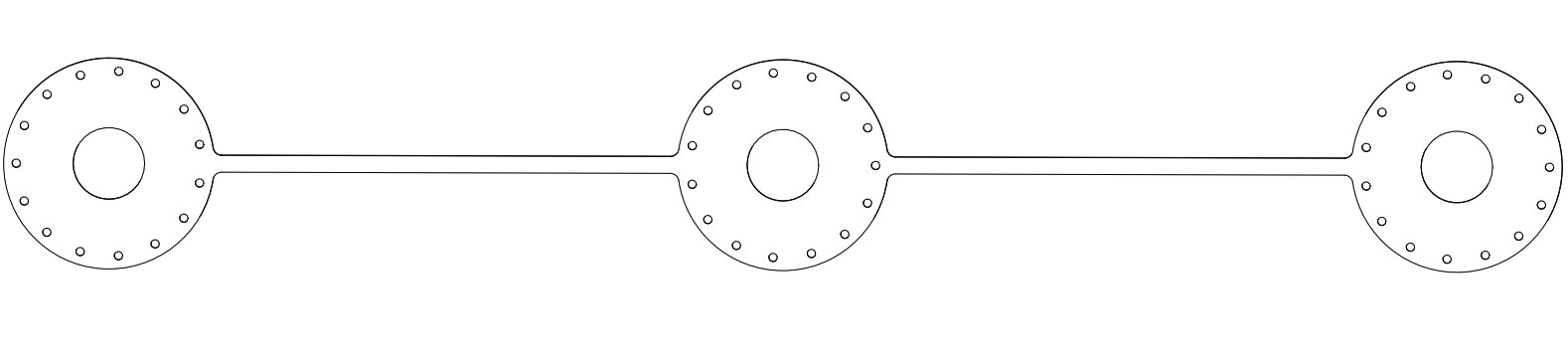

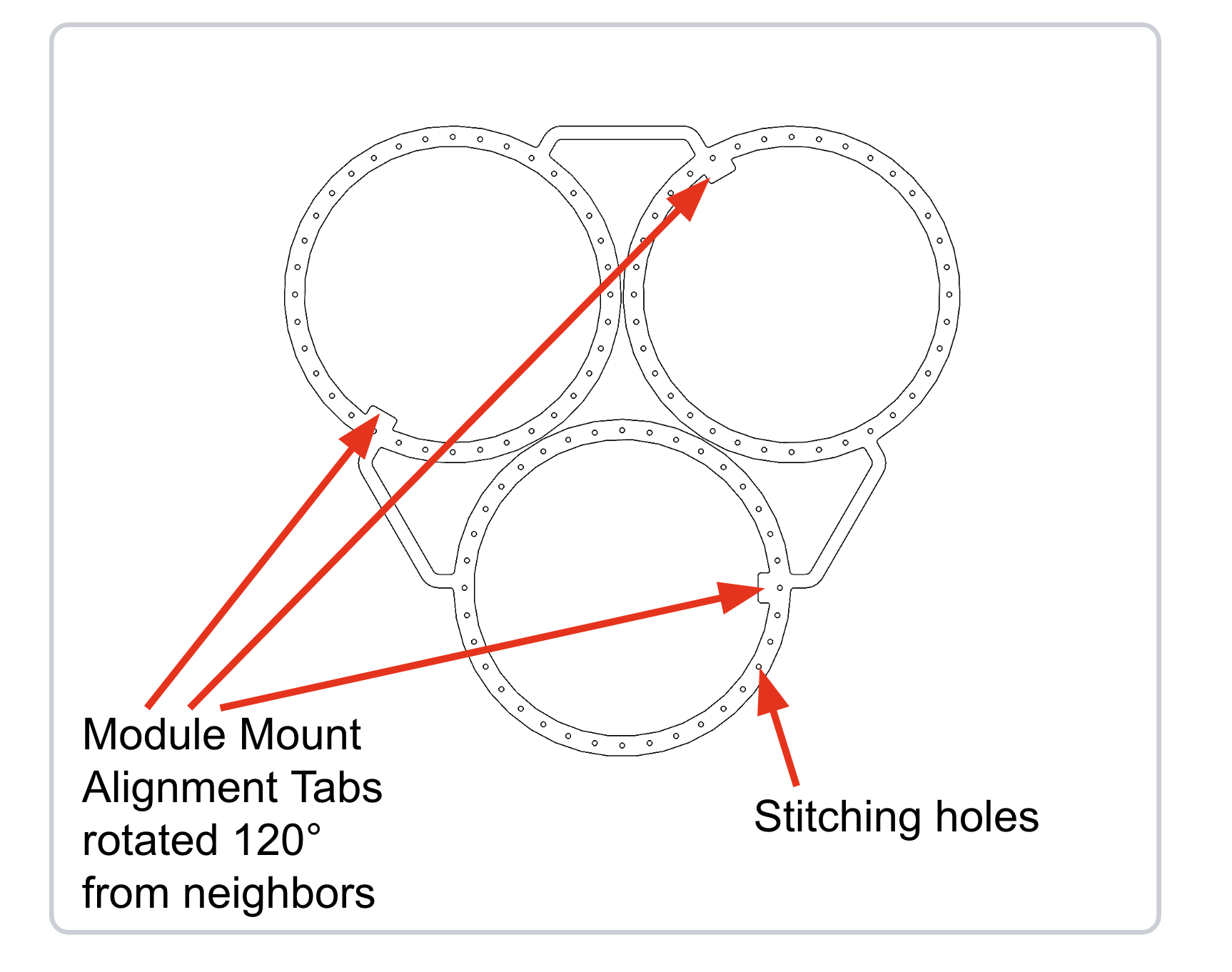

If you choose to design your own guides using CAD or 2D vector software, you must adhere to the following mechanical constraints to ensure hardware compatibility:

- Minimum Spacing: Maintain a center-to-center distance of at least 50.5mm.

- Alignment Tabs: Position adjacent tabs 120° apart.

- Stitching Holes: Add holes around the perimeter of each ring.

- Sizing should be as small as your needle allows to maximize long-term durability.

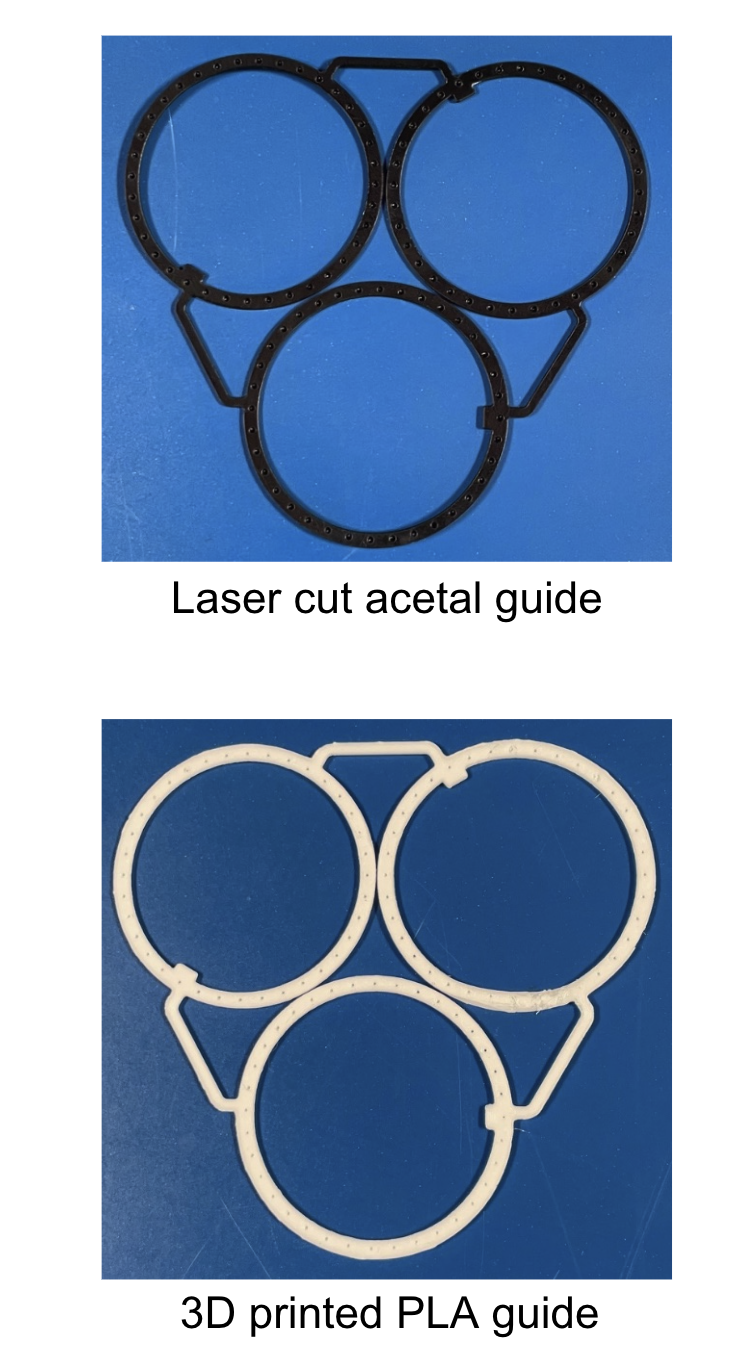

Fabrication

Once you have finalized your standardized templates or custom designs, the next step is physical fabrication. The choice of material depends on your available fabrication method.

- For laser cut position guides, 3/64” Delrin are suggested.

- For guides 3D printed by a 3rd party such as Protolabs, unfilled MJF PA12 is suggested.

- For guides 3D printed on a low-cost filament printer, toughened PLA is suggested. Note that this material is more fragile than the previous two, but still useable if carefully handled.

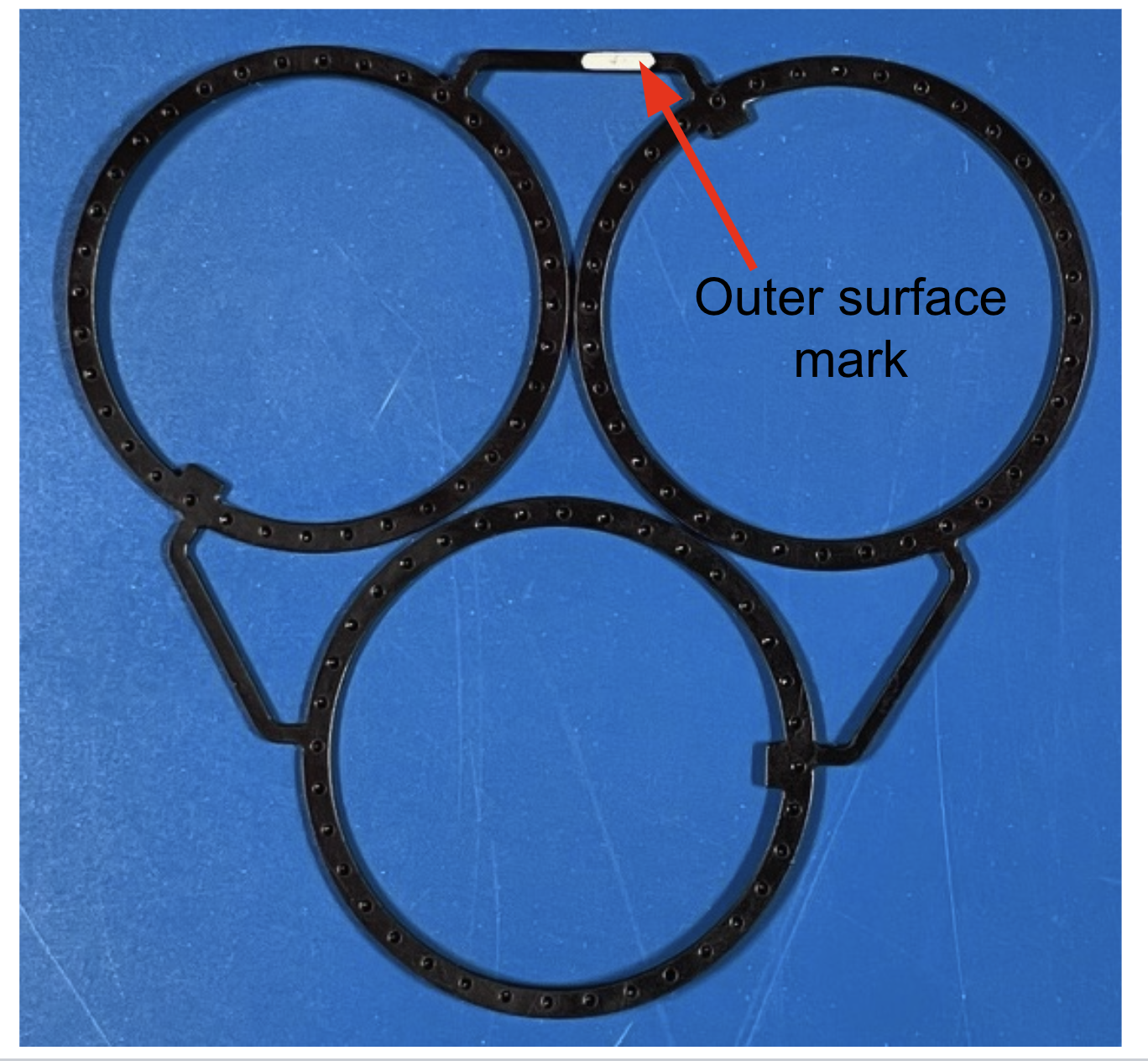

Once printed, mark the outer surface of each guide immediately to maintain intended module orientation. Note that stitching hole size may need to be adjusted based on method – laser cut holes frequently require smaller holes while filament printers require larger. Check the fit of your intended sewing needle before proceeding.